Frac Tanks

A Frac Tank is a large, portable heavy steel storage tank. Typically holding up to 21,000 gallons (500 BBL), it readily provides storage for fresh water, waste water, fuel, chemicals, fertilizers, and many more. Easily pulled by a truck to the job site, it can be moved/emptied as the need arises. Below you can explore different types of tanks and their typical uses. Also check out Industries Served.

Featured Frac Tanks

.jpg)

Flat Top Tanks

The most popular type of Frac Tank, the Flat Top boasts 21,000 gallons (500 BBL) of storage. Economical and convenient, it is widely used across a variety of industries. In the environmental industry, flat top frac tanks are helpful for storing wastewater, chemicals and fuel. Want to learn more? Check out our Closer Look at Flat Top Tanks post.

TYPICAL USES

- Fracking site storage for sand and water

- Groundwater remediation

- Septic wastewater storage

- Freshwater storage

- Manure management

- Calcium Chloride

.jpg)

Slope Top Tanks

The Slope Top tank is similar to its cousin, the Flat Top. It boasts a 21,000-gallon (500 BBL) capacity, but has a shorter length. Its sloped design gives it a tighter turning radius to maneuver well on farm roads and in tight places. Learn more in our post: A Closer Look at Slope Top Tanks

TYPICAL USES

- Agricultural applications: manure management, chemical fertilizing, fuel storage

Open Top Tanks

The 21,000-gallon (500 BBL) open top frac tank can store a variety of liquids. This includes freshwater, wastewater, and occasionally fuel. The open top makes it simple to check fluid levels and allows easy access for cleaning the tank after a job.

TYPICAL USES

- Freshwater storage in construction and agricultural industries

- Storing liquids like run-off water, diesel fuel, glycol, and oils in the environmental, agricultural, energy, construction, and chemical industries

Double Wall Tanks

A 16,000-gallon Double Wall is the tank of choice when environmental concerns run high. Its second internal wall assures the highest standards when dealing with dangerous chemicals. This is especially critical when operating near freshwater areas.

TYPICAL USES

- Containment of dangerous chemicals in environmental applications near fresh water

- Agricultural applications with Mandatory EPA requirements

- Secondary containment of petroleum storage

Gas Buster Tanks

Gas buster tanks enhance safety by preventing the buildup of dangerous combustible material. They stabilize the thickness of mud and oil emanating from the oil drilling process. Its special design allows gasses to escape from a top vent while fluids dispense from the bottom of the tank.

TYPICAL USES

- Remove free or entrained gas from fluids circulated in the wellbore, such as mud used during drilling operations

- Stabilize mud viscosity while preventing blowouts and keeping the oilfield job site safe

- Perfect for use while flowing back a well

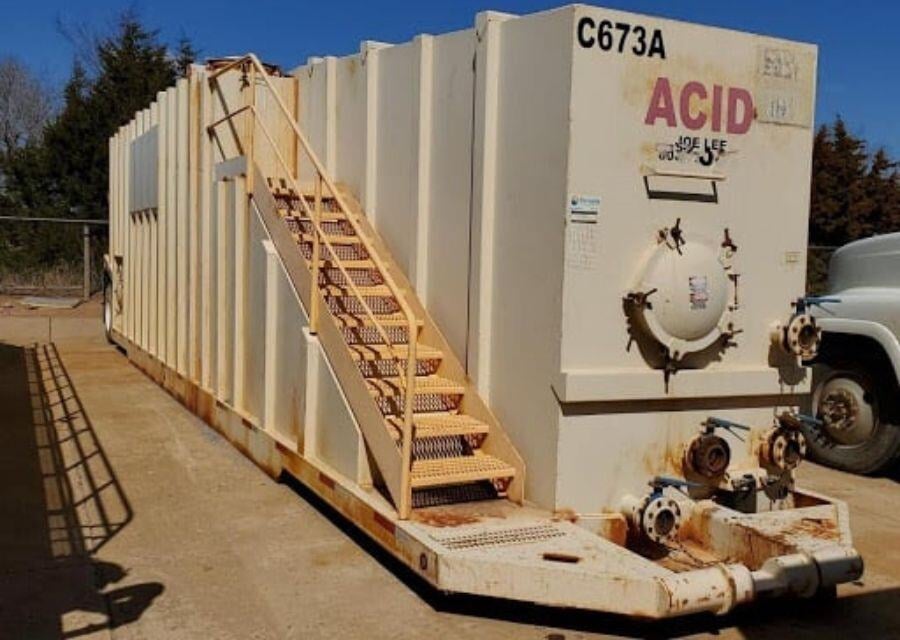

Acid Tanks

Acid tanks are specially designed for high acid resistance. Great for storing hydrochloric acid (HCL) at the job site, most tanks are 21,000 gallons (500 BBL) in size and can handle HCL in concentrations between 15% and 32%.

TYPICAL USES

- These tanks are great for storing hydraulic fluid.

- Storing acids used to acidize petroleum wells

- For use with heavyweight chemicals like sulfuric acid

Weir Tanks

Weir tanks have a storage capacity of 18,100 gallons. As the name, weir implies, these tanks control the flow of liquid and particulates in the tank. Over and under weirs speed up the settling of solids, particulates, and floating oils. Some Weir Tanks have a “V” shaped floor designed to drain stored liquids from underneath with ease.

TYPICAL USES

- Oilfield application when it is necessary to separate oils from particulates

- Jobs needing solid & sediment separation, with the ability to drain stored liquids from underneath

- Projects needing a portable tank that can quickly move from one location to another for disposal and/or filtration of contents

Mud Tanks

When your job requires the separation of materials at the job site, the 21,000 gallon (500 BBL) Mud Tank delivers. Storing fluid and rock fragments transported to the surface from an oil well is a typical use in oilfield applications.

TYPICAL USES

- Fracking wells in the oil and gas industry

- Storage of drilling fluid on a drilling rig

- Separating drilling mud from the cuttings for recycling

- Freshwater storage in advance of fracking